Hammar sideloader trailer are primarily used for loading, unloading, and transporting 20 foot and 40 foot containers, and can operate independently in areas without forklifts or cranes. Hammar container side loader trailer are particularly suitable for container handling tasks in ports, logistics parks, factories, and remote areas.

Hammar side loader price in Papua New Guinea are equipped with dual-side hydraulic lifting systems, enabling self loading and unloading of containers with flexible and efficient operation. Utilizing high strength steel and a reinforced chassis, trailer side loader maintain stability and durability even under heavy loads.

Max. lifting capacity: 37 Ton

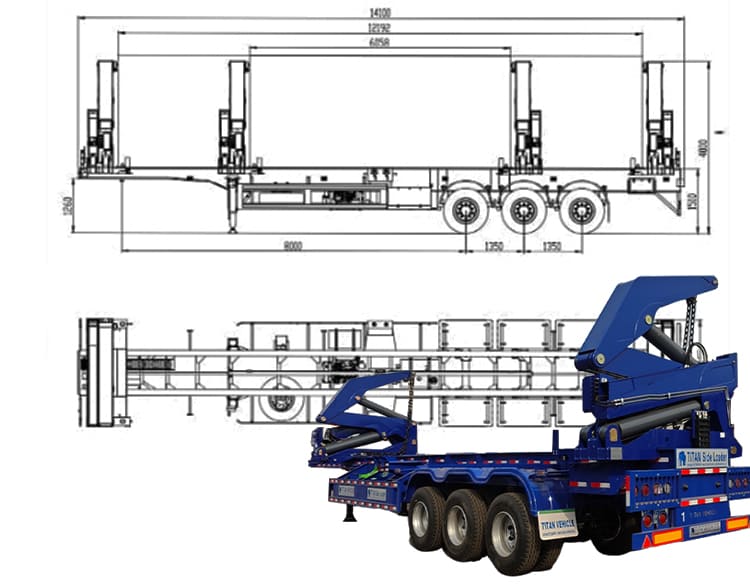

Dimension(L*W*H): 14100*2500*4200mm

Axle: 3 axle, 16 ton

Tire: 12 pcs, 12R22.5

Suspension: Mechanical suspension

Kingpin: 3.5-inch bolted type

Landing gear: JOST Brand

Power source: Power take-off (equipped)

As highly efficient equipment for container transport, hammar container side loader trailer possess core advantages such as autonomous loading and unloading, wide adaptability to various scenarios, and stable transport safety. Without relying on external cranes, hammar side loader price in Papua New Guinea can independently complete container loading and unloading operations, significantly reducing requirements for site equipment and making them suitable for various scenarios including ports, warehouses, and construction sites. Hammar sideloader trailer are compatible with various container sizes, including 20 foot and 40 foot, accommodating both general and heavy cargo transport. Their enclosed transport design provides rain and dust protection, ensuring cargo integrity and making them highly favored by the logistics and engineering industries.

The boom, the core operating component of the trailer side loader in Papua New Guinea, is forged from high strength alloy steel and heat treated for enhanced fatigue resistance. It allows for 360-degree rotation and multi angle extension, easily completing lateral container transfer and precise positioning.

The hammar container side loader trailer's boom is equipped with a hydraulic buffer system, ensuring smooth lifting and lowering to prevent cargo impact damage. Operation is via an electronic control handle, offering high precision.

The hammar side loader price's landing gear utilize a dual speed hydraulic structure, allowing for flexible adjustment of the support span. Combined with thickened alloy support plates, they provide strong support during loading and unloading, effectively distributing the hammar sideloader trailer's weight, preventing tilting, and adapting to varying terrain hardness.

The trailer side loader in Papua New Guinea's container lock is made of forged alloy steel with a wedge shaped locking structure, firmly securing the container corners and preventing displacement due to bumps during transport. Operation is convenient, allowing for quick locking and unlocking.

Hammar container side loader trailer in Papua New Guinea's mechanical suspension uses a multi-leaf spring combination with shock absorber design, providing superior impact resistance. It effectively filters road bumps, protecting cargo and the vehicle structure. The leaf springs undergo heat treatment, resulting in high wear resistance and a long service life.

In addition, the hammar side loader price adopts cathodic electrophoresis and powder coating process, which has excellent corrosion resistance and is suitable for humid coastal or dusty construction site environments. It combines efficient operation with durability and is an ideal choice for comprehensive transportation.