RS45 31ch reach stacker are mainly used for loading, unloading, and short distance transfer of containers and heavy cargo. Reach truck stacker are commonly found in ports, yards, and logistics centers, and can quickly complete container stacking and handling operations.

The rs45 31ch reach stacker cost in Mexico is a highly efficient vehicle combining container handling equipment and transport, possessing powerful lifting and mobility capabilities. Reachstackers outilizes a hydraulic control system and a stable chassis structure, easily handling heavy loads and complex working conditions.

RS45 31CH Reach Stacker Truck | Electric Reachstackers in Mexico

RS45 31CH Reach Stacker Truck | Electric Reachstackers in Mexico

RS45 31CH Reach Stacker Truck | Electric Reachstackers in Mexico

RS45 31CH Reach Stacker Truck | Electric Reachstackers in Mexico

RS45 31CH Reach Stacker Truck | Electric Reachstackers in Mexico

RS45 31CH Reach Stacker Truck | Electric Reachstackers in Mexico

Vehicle Model: XCS model 45t

Dimension(L*W*H): 11340*6053*4670 mm

Engine Model: X12CS4350

Engine Rated Power: 261kw

Rated Lifting Capacity: 45T

Max. Lifting Height: 15100mm

Total Vehicle Curb Weight: 71200kg

Max. Design Travel Speed: 25km/h

As an integrated high efficiency logistics transport and loading/unloading equipment, the core advantage of the stacker reach truck in Mexico lies in its seamless integration of transportation and loading/unloading, significantly simplifying the operational process. RS45 31ch reach stacker cost eliminates the need for additional lifting equipment, making it particularly suitable for cargo transfer in various scenarios such as ports, warehouses, and construction sites, significantly improving overall operational efficiency.

Electric reach stacker forklift's overall structure employs a lightweight, high strength steel design, reducing its own weight while ensuring rated load capacity, thus reducing fuel consumption and balancing economy and durability. Electric reach stacker truck can withstand long term, high intensity operation in complex road conditions.

The spreader, as the core operating component of rs45 31ch reach stacker brands in Mexico, uses an adjustable clamping structure, adaptable to containers of different sizes from 20 feet to 40 feet. The clamping force can be precisely adjusted, ensuring secure clamping of cargo while preventing over clamping and damage.

The spreader is equipped with a rotating mechanism on top, supporting 360 degree flexible steering, easily completing horizontal rotation and alignment of cargo, significantly reducing the difficulty of operating in confined spaces.

The hydraulic cylinders of reach truck stacker in Mexico utilize a high strength alloy cylinder body and a precision sealing structure, offering excellent pressure resistance and stable, powerful lifting force. The lifting speed is uniform and controllable, preventing cargo jolting during lifting. Seals are made of high and low temperature resistant and wear resistant materials, effectively preventing hydraulic oil leakage, extending service life, and adapting to various climatic environments.

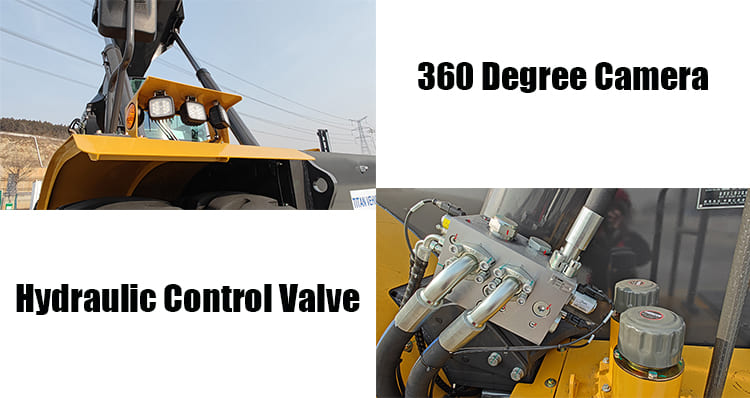

The hydraulic system of reachstackers features an integrated design with a compact and rational pipeline layout, fast response speed, and smooth switching between actions. It enables coordinated control of lifting, rotating, and vehicle posture adjustment of the spreader. The system is equipped with a pressure protection device that automatically shuts down when the load exceeds the rated value, mitigating overload risks from the outset and improving operational safety of stacker reach truck.

The cab of rs45 31ch reach stacker cost in Mexico features a floating shock absorbing design, equipped with an adjustable seat and a multi functional control panel. The ergonomically arranged buttons reduce fatigue during long term operation. The cab of electric reach stacker forklift offers excellent visibility, and combined with high definition cameras around the vehicle, it transmits 360 degree images to the central control screen in real time. Combined with the reversing radar alarm function, blind spots are effectively eliminated, ensuring the safety of personnel and cargo during loading, unloading, and transportation.